Product name: Single flute end mill for wood

Product material: Tungsten steel alloy

Tips: Prices fluctuate with raw materials and exchange rates, leave your contact information, the first time to give you a latest quotation.

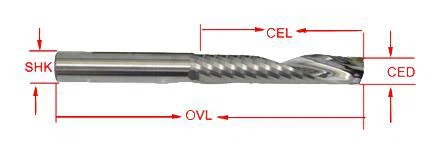

Product Spesification

| NO | SHK | CED | CEL | OVL |

| krxcncs1-6-1 | 3.175 | 1.5 | 7 | 38.5 |

| krxcncs1-6-2 | 3.175 | 1.5 | 12 | 38.5 |

| krxcncs1-6-3 | 3.175 | 2 | 8 | 38.5 |

| krxcncs1-6-4 | 3.175 | 2 | 10 | 38.5 |

| krxcncs1-6-5 | 3.175 | 2 | 12 | 38.5 |

| krxcncs1-6-6 | 3.175 | 2 | 15 | 38.5 |

| krxcncs1-6-7 | 3.175 | 2 | 17 | 38.5 |

| krxcncs1-6-8 | 3.175 | 2.5 | 12 | 38.5 |

| krxcncs1-6-9 | 3.175 | 2.5 | 15 | 38.5 |

| krxcncs1-6-10 | 3.175 | 2.5 | 17 | 38.5 |

| krxcncs1-6-11 | 3.175 | 2.5 | 22 | 45 |

| krxcncs1-6-12 | 3.175 | 3.175 | 12 | 38.5 |

| krxcncs1-6-13 | 3.175 | 3.175 | 15 | 38.5 |

| krxcncs1-6-14 | 3.175 | 3.175 | 17 | 38.5 |

| krxcncs1-6-15 | 3.175 | 3.175 | 22 | 45 |

| krxcncs1-6-16 | 3.175 | 3.175 | 25 | 50 |

| krxcncs1-6-17 | 3.175 | 3.175 | 28 | 50 |

| krxcncs1-6-18 | 3.175 | 3.175 | 32 | 55 |

| krxcncs1-6-19 | 4 | 4 | 12 | 45 |

| krxcncs1-6-20 | 4 | 4 | 15 | 45 |

| krxcncs1-6-21 | 4 | 4 | 17 | 45 |

| krxcncs1-6-22 | 4 | 4 | 22 | 45 |

| krxcncs1-6-23 | 4 | 4 | 25 | 50 |

| krxcncs1-6-24 | 4 | 4 | 28 | 50 |

| krxcncs1-6-25 | 4 | 4 | 32 | 55 |

| krxcncs1-6-26 | 4 | 4 | 42 | 65 |

| krxcncs1-6-27 | 6 | 6 | 17 | 50 |

| krxcncs1-6-28 | 6 | 6 | 22 | 50 |

| krxcncs1-6-29 | 6 | 6 | 25 | 50 |

| krxcncs1-6-30 | 6 | 6 | 28 | 60 |

| krxcncs1-6-31 | 6 | 6 | 32 | 60 |

| krxcncs1-6-32 | 6 | 6 | 35 | 65 |

| krxcncs1-6-33 | 6 | 6 | 38 | 70 |

| krxcncs1-6-34 | 6 | 6 | 42 | 70 |

| krxcncs1-6-35 | 6 | 6 | 52 | 80 |

| krxcncs1-6-36 | 8 | 8 | 22 | 60 |

| krxcncs1-6-37 | 8 | 8 | 25 | 60 |

| krxcncs1-6-38 | 8 | 8 | 32 | 60 |

| krxcncs1-6-39 | 8 | 8 | 42 | 75 |

| krxcncs1-6-40 | 8 | 8 | 52 | 85 |

| krxcncs1-6-41 | 8 | 8 | 62 | 100 |

Product application:

Solid wood, MDF, Multilayer board and so on.

Product advantages:

1, Selection of tungsten steel: Choose better raw material.

2, 25°spiral angle, no burr.

3, Large screw design, quite sharp, smooth chip evacuation.

4, Independent packaging, better protection of the cutters.

FAQ:

1, Q: What is the processing speed of this tool?

A: Recommended spindle speed 24000 RPM. The feed speed of multi-layer board special cutter with handle diameter below 3.175mm is 3-5m/min and density board special cutter needs reach 6-8 m/min. The feed speed of density plate with handle diameter of 4mm and 6mm needs reach 10m/min.